PRODUCTS

CONTACT US

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

Cambodia T16 Wholesale Three Rollers Rolling Machine Factory Price

Category:

CambodiaThree-axis thread rolling machine

Product Description

T16 Wholesale Three Rollers Rolling Machine Factory Price

Three rollers rolling machines are widely used in metal fabrication workshops for forming steel plates into cylinders, cones, and curved parts. This type of plate rolling machine uses three rollers arranged in a triangular layout to apply pressure and gradually shape the metal sheet.

What Is a Three Rollers Rolling Machine?

A three rollers rolling machine is a plate forming equipment designed to bend and roll sheet metal into cylindrical shapes. It can handle mild steel, stainless steel, aluminum, and alloy plates. These machines are commonly used in tank manufacturing, ducting work, pressure vessels, and metal structure workshops.

Yushi Machinery, as one of the most professional wholesale three-roller rolling machine manufacturers, has the following advantages:

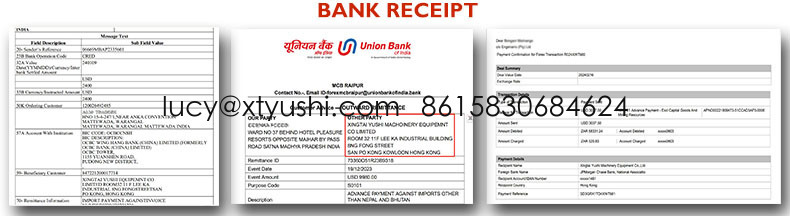

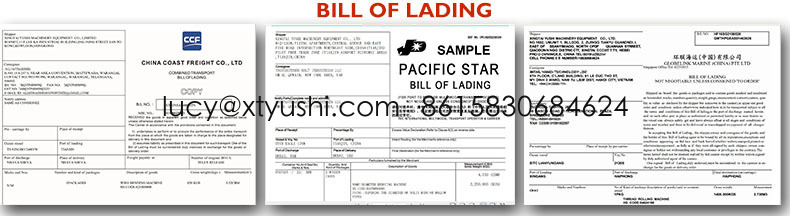

We are the leader thread rolling machine supplier in China, and we also have customers worldwide, such as in America, Argentina, Brazil, Belarus, Bangladesh, Paraguay, Virgin Islands, Paracel Islands, Lesotho, Guyana, Glorioso Islands, and Italy. We are a factory specializing in the manufacture and export of thread rolling machines for more than 20 years; all of the products we sell are at a very good price and of high quality.

We take care of our product quality; for any defect of the goods, we will take responsibility. You are risk-free.And we believe that the good quality products will can give us survival, so we always offer the top quality products to our customers to keep them having the competitiveness in their market.

T16 Three Rollers Rolling Machine Technical Parameters

| Item | parameter | |

| thread rolling thread range | max diameter | ∅160mmm |

| max pitch | 16mm | |

| spindle Angle | ±6° | |

| maxmum rolling pressure | 1200kn | |

| spindle RPM | sInfinitely variable speed0-25r、min | |

| thread roller range | outer diameter | ∅230-270mm |

| innner diameter | ∅·100mm | |

| max width | 200mm | |

| rolling time | 0.1-99.9s | |

| pause time | 0.1-99.9s | |

| spindle drive power | 22kw | |

| hydraulic transmission power | 15kw | |

| physcial size | 2900*2200*2500mm | |

| machine weight | 8200kg | |

Types of Three Roller Rolling Machines

Manual Three Roller Rolling Machine

Suitable for small workshops and thin sheet processing. Low cost and easy to operate.

Mechanical Three Roller Rolling Machine

Driven by a motor, suitable for medium-size sheet rolling applications.

Hydraulic Three Roller Rolling Machine

Provides higher bending force and is ideal for heavy-duty rolling of thick plates.

Factors Influencing Factory Price

| Factor | Influence on Price |

|---|---|

| Plate thickness capacity | Higher thickness = higher price |

| Working width (roller length) | Longer rollers = higher cost |

| Hydraulic vs mechanical system | Hydraulic systems cost more |

| CNC or manual operation | CNC increases automation and precision |

| Customization needs | Custom dies or roller material may affect cost |

Typical Factory Price Range

Manual 3 Roll Machine: USD $1,200 – $3,000

Mechanical 3 Roll Machine: USD $3,500 – $12,000

Hydraulic CNC 3 Roll Machine: USD $12,000 – $85,000+

(Exact prices depend on size, roller diameter, and thickness capacity.)

How to Choose the Right Three Rollers Rolling Machine

Determine Your Working Material Specifications

Plate material (carbon steel, stainless steel, aluminum)

Thickness and width

Confirm Output Requirements

Cylinder diameter

Production volume

Choose Hydraulic or Mechanical Based on Workload

Why Buy Direct from Factory?

Factory pricing reduces distributor markup

Direct customization support

Faster delivery and stable after-sales service

OEM and ODM support available

wholesale three rollers rolling machine services FAQs Guide

Are you looking for a quick review guide about wholesale three rollers rolling machine services?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding wholesale three rollers rolling machine services.

Let’s continue!

1.How does a wholesale three rollers rolling machine contribute to the accuracy and precision of threaded parts?

2.Can a wholesale three rollers rolling machine create threads on curved or irregular surfaces?

3.What is the Typical Lifespan of a wholesale three rollers rolling machine?

4.What Types of Materials can be Used with a wholesale three rollers rolling machine?

5.Is training required to operate a wholesale three rollers rolling machine?

6.Can a wholesale three rollers rolling machine create threads on hardened materials?

7.What are the Advantages of Using a wholesale three rollers rolling machine in Production?

8.What materials can be used with a wholesale three rollers rolling machine?

9.How Does the Size and Shape of Threads Created by a wholesale three rollers rolling machine Affect Their Performance?

10.What safety precautions should be taken when operating a wholesale three rollers rolling machine?

11.What are the Limitations of a wholesale three rollers rolling machine?

12.What are the most common applications for a wholesale three rollers rolling machine?

13.Is a wholesale three rollers rolling machine Suitable for High Volume Production?