PRODUCTS

CONTACT US

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

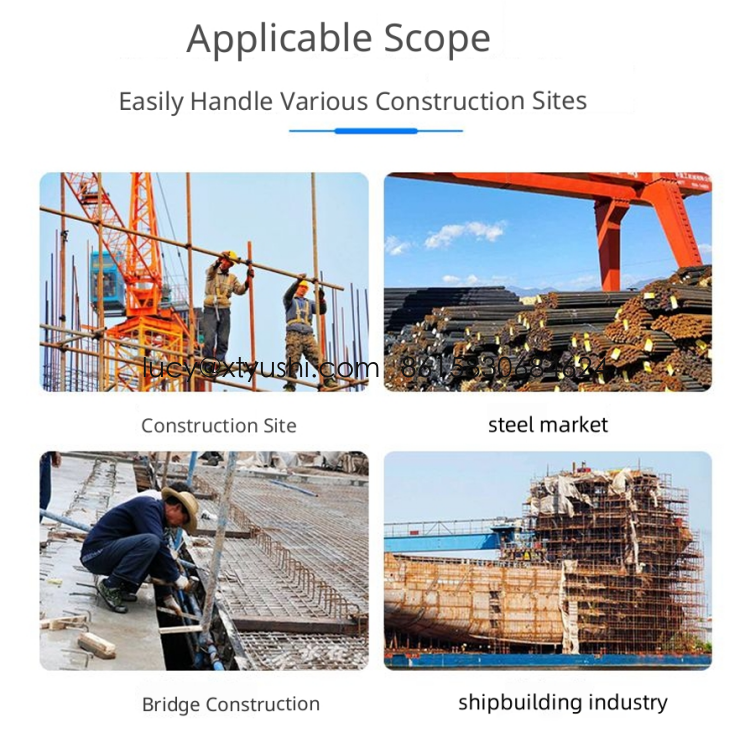

Papua New Guinea R9 stirrup bending machine quotes automatic stirrup bending machine germany

Category:

Papua New GuineaStirrup Bending Machine

Product Description

R9 stirrup bending machine quotes automatic stirrup bending machine germany

R9 stirrup bending machine Technical parameter

| Model | R9 | (mm) Single Wire | 5-14 |

| (mm) Double Wire | 5-12 | Max Bending Angie | 180 |

| (m/min) Max Bending Angle | 100 | Max Bending Speed | 1400 |

| (mm) Length Accuracy | 1 | < Angie Accuracy | 1 |

| Weight | 3100kg | Dimension LXBXH (mm) | 3610*1510*2310 |

R9 stirrup bending machine quotes machine component brand name

| Part name | Brand | parameter |

| Feeding motor | OREN | 18KW |

| Bending motor | OREN | 7.5KW |

| Air compressor motor | - | 4kw |

| Air compressor | 0.8㎡ | |

| CNC system | kinco | |

Accessories of the stirrup bending machine quotes for free:

| N/M | Part name | quantity |

| 1 | Cutting knife | 2 pcs |

| 2 | Dead knife | 1 piece |

| 3 | Machine head | 2 pcs |

| 4 | Feeding head | 1 pcs |

| 5 | Tool | 1 set |

FAQ

How does stirrup bending machine quotes automatic stirrup bending machine germany contribute to a greener environment?

1. Reducing material waste: A stirrup bending machine is designed to accurately bend steel bars into specific shapes, minimizing the amount of material waste. This reduces the need for additional raw materials, which in turn reduces the environmental impact of mining and manufacturing processes.

2. Energy efficiency: Stirrup bending machines are designed to be energy-efficient, using less power to operate compared to manual bending methods. This helps to reduce energy consumption and lower carbon emissions, contributing to a greener environment.

3. Decreased carbon footprint: By automating the bending process, stirrup bending machines reduce the need for manual labor, which in turn reduces the carbon footprint associated with transportation and commuting.

4. Recycling capabilities: Many stirrup bending machines are equipped with recycling capabilities, allowing them to recycle scrap steel and reuse it for future projects. This reduces the need for new steel production, which is a major contributor to greenhouse gas emissions.

5. Reduced noise pollution: Stirrup bending machines operate quietly, reducing noise pollution in the surrounding environment. This is especially beneficial in urban areas where construction noise can be a major source of disturbance.

6. Faster construction process: By automating the bending process, stirrup bending machines can significantly increase the speed of construction projects. This reduces the overall time required for construction, minimizing the environmental impact of the project.

7. Precision and accuracy: Stirrup bending machines are designed to bend steel bars with precision and accuracy, reducing the need for rework and minimizing material waste. This helps to conserve resources and reduce the environmental impact of construction projects. 8. Durability and longevity: Stirrup bending machines are built to last and require minimal maintenance, reducing the need for frequent replacements. This helps to conserve resources and reduce the environmental impact of manufacturing new machines.