PRODUCTS

CONTACT US

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

Peru Z28-185 good price and quality thread rolling machine hydraulic thread rolling machine supplier

Category:

PeruTwo-axis thread rolling machine

Product Description

Z28-185 good price and quality thread rolling machine hydraulic thread rolling machine supplier

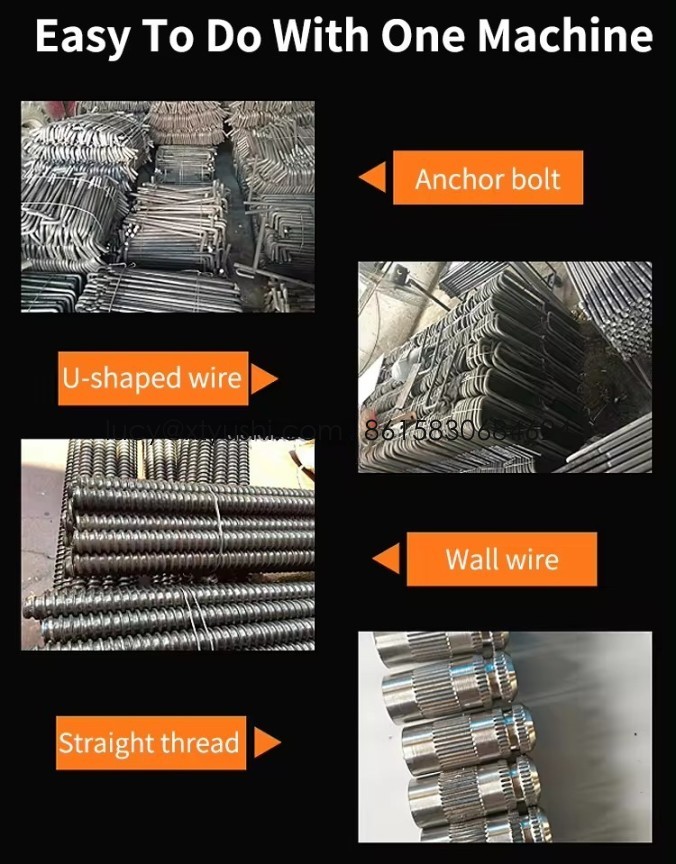

A mass of screws can be precisely made by thread rolling machines with thread rolling dies. “Cold forming” is the most appropriate description of thread rolling progress. Place a round material blank in the between of thread rolling dies. The die thread penetrates the blank surface to form the thread roots and displaces material outward form the crest. This is the basic theory for thread rolling.

Z28-185 thread rolling machine is the medium size for the hydraulic thru feed type. The suitable work range of the screw diameters, you may check the specification table as below.

Z28-185 thread rolling machine is actually a very popular model. As well as its capacity. The customers who are in the field electrical shafts, machine parts, bicycle parts are very suitable for choosing Z28-150 thread rolling machine.

Z28-185 good price and quality thread rolling machine hydraulic thread rolling machine supplier specification sheet

| Items | Parameters | |

| Thread rolling thread range | diamete | φ60mm |

| thread pitch | 6mm | |

| Spindle Angle | ±10° | |

| Maximum rolling pressure | 250kn | |

| Spindle RPM | Exchange gear 22/28/35/45/56/70rpm | |

| Thread rolling wheel range | diameter | φ210mm |

| aperture | φ75mm | |

| Maximum width | 160mm | |

| Rolling time | 0.1-99.9s | |

| Pause time | 0.1-99.9s | |

| Spindle drive power | 11kw | |

| Hydraulic transmission power | 3.0kw | |

| Cutting oil Pump driving motor | 90w | |

| Physical size | 1800×1600×1450mm | |

| Machine weight | 2100kg | |

FAQ

What are the Main Components of a work instruction for good price and quality thread rolling machine hydraulic thread rolling machine supplier?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

1. Bed: The bed is the main structural component of a thread rolling machine. It provides a stable base for all other components and supports the weight of the machine.

2. Headstock: The headstock is the part of the machine that holds the workpiece and rotates it during the thread rolling process. It also houses the drive mechanism for the workpiece rotation.

3. Tailstock: The tailstock is the part of the machine that supports the other end of the workpiece and provides stability during the thread rolling process.

4. Spindle: The spindle is the rotating shaft that holds the thread rolling dies. It is driven by the headstock and rotates the workpiece during the thread rolling process.

5. Thread Rolling Dies: These are the tools that actually form the threads on the workpiece. They are made of hardened steel and come in various sizes and shapes depending on the type of thread to be rolled.

6. Feed Mechanism: The feed mechanism is responsible for moving the thread rolling dies towards and away from the workpiece. It is usually controlled by a hydraulic or mechanical system.

7. Control Panel: The control panel is where the operator can set and adjust the parameters of the thread rolling process, such as the speed, feed rate, and depth of the thread.

8. Lubrication System: Thread rolling machines require a constant supply of lubricant to reduce friction and heat during the rolling process. The lubrication system ensures that the dies and workpiece are properly lubricated.