Industry Scheme of Automatic Thread Rolling Mchine for Improving Production Efficiency

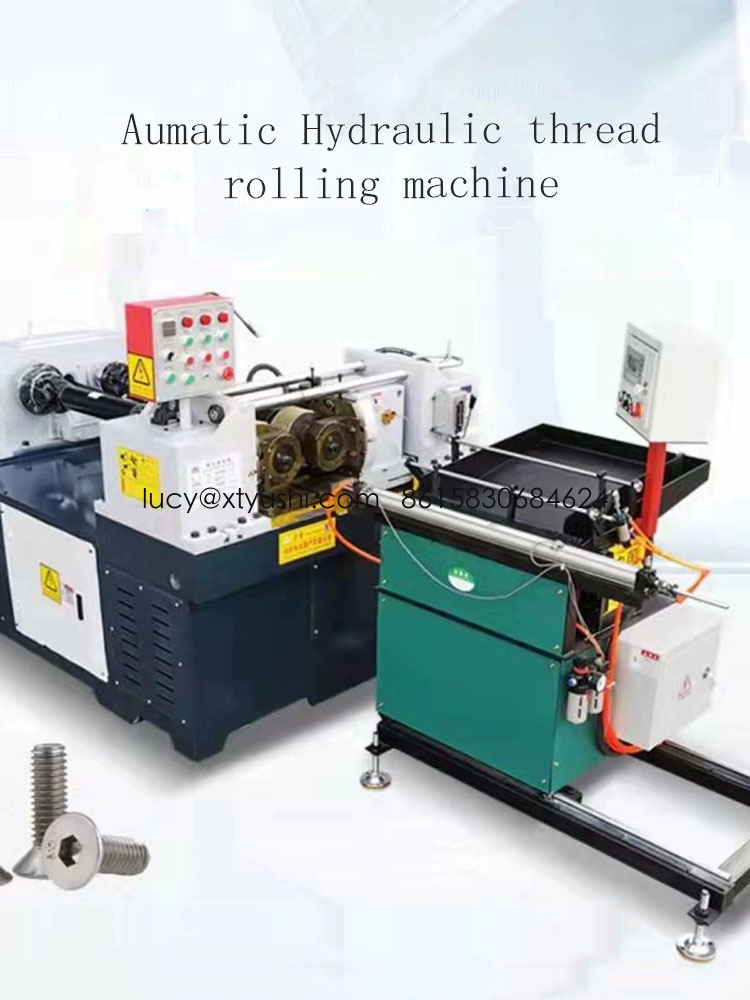

As a highly efficient automatic mechanical equipment, automatic thread rolling Machine is widely used in automobile manufacturing, aerospace, furniture and other industries. Its main function is to process metal materials into products with standard threads by rolling. Compared with the traditional manual operation, the automatic thread rolling machine has higher processing accuracy and stability, which greatly improves the production efficiency.

In modern manufacturing, efficiency, precision, and automation are crucial to maintaining competitiveness. One of the most advanced solutions for improving production efficiency in metal processing is the automatic thread rolling machine. As a manufacturer specializing in industrial automation equipment, we recognize the growing demand for high-performance thread rolling machines in sectors such as automobile manufacturing, aerospace, construction, and heavy machinery.

Automatic thread rolling machines are designed to enhance productivity, ensure precision, and reduce manual labor in thread production. By rolling metal materials into standardized threaded products, these machines eliminate the limitations of traditional manual threading processes, such as inconsistencies, slow production rates, and increased labor costs. With technological advancements and increasing demand for high-quality, standardized threaded components, the adoption of automatic thread rolling machines has become a necessity across various industries.

Key Advantages of Automatic Thread Rolling Machines

1. Improved Production Efficiency

Compared to conventional manual or semi-automatic threading techniques, automatic thread rolling machines can increase production speed by up to 300%. This efficiency gain is particularly beneficial for high-volume industries such as automobile and aerospace manufacturing, where precision-threaded components are produced on a large scale.

2. Superior Thread Quality and Consistency

Thread rolling machines provide high precision and uniformity in thread production, ensuring that each component meets strict industry standards. Traditional cutting or manual threading techniques often lead to variations, but automatic thread rolling guarantees error-free, defect-free threads with consistent dimensions.

3. Cost-Effectiveness and Labor Reduction

With automation, companies can significantly reduce reliance on manual labor. The integration of automatic thread rolling machines can lower labor costs by up to 40%, while simultaneously minimizing material waste. This makes it an excellent investment for manufacturers looking to optimize cost efficiency while improving output.

4. Enhanced Durability and Strength of Threaded Parts

Thread rolling does not involve material removal, unlike conventional thread cutting methods. Instead, it strengthens the metal by cold working, making the threads more durable and resistant to wear and tear. This is particularly important in industries where high-strength components, such as aircraft and automotive parts, are required.

Industry Applications of Automatic Thread Rolling Machines

1. Automotive Industry

The automotive sector relies heavily on threaded components, such as bolts, nuts, and studs, which require high precision and consistency. Automatic thread rolling machines help manufacturers maintain stringent quality standards while reducing production cycles by up to 50%. The precision provided by these machines enhances the safety and reliability of automotive components.

2. Aerospace Industry

Aircraft components demand exceptional accuracy, durability, and compliance with international safety standards. In aerospace manufacturing, a single defect can lead to critical failures, making precision-threaded parts essential. Automatic thread rolling machines ensure high-tolerance threading with minimal deviation, increasing both production efficiency and safety compliance.

3. Construction and Infrastructure

The construction industry depends on high-strength threaded fasteners used in steel structures, bridges, and high-rise buildings. Thread rolling machines provide stronger, wear-resistant threads that withstand high stress and environmental conditions, making them an ideal choice for large-scale construction projects.

4. Heavy Machinery and Industrial Equipment

Industrial machinery requires robust threaded components that can endure extreme loads and conditions. Automatic thread rolling machines enhance production efficiency and extend the lifespan of components by producing high-strength, wear-resistant threads suitable for heavy-duty applications.

Market Trends and Industry Growth

The global thread rolling machine market is experiencing significant growth, driven by automation in manufacturing and increasing demand for high-precision fasteners. According to market research, the thread rolling machine industry is projected to grow at a CAGR of 5.8% from 2023 to 2030. Factors contributing to this growth include:

The rising demand for precision engineering components in automotive and aerospace sectors.

Advancements in CNC-based thread rolling machines, improving speed and precision.

The increasing focus on reducing labor costs and enhancing production efficiency.

Why Choose Our Automatic Thread Rolling Machines?

As a leading manufacturer of industrial thread rolling solutions, we are committed to providing high-quality, durable, and efficient machines tailored to meet the demands of modern industries. Our machines are designed with the latest technology to ensure maximum productivity and minimal maintenance.

Our Key Competitive Advantages:

Precision Engineering – We manufacture machines with high-accuracy rolling mechanisms to ensure perfect thread formation.

Advanced Automation Features – Our machines come with CNC controls and smart sensors for enhanced efficiency and real-time monitoring.

Energy Efficiency – Our models consume 20% less power than conventional thread rolling machines, reducing operational costs.

Customization Options – We provide solutions tailored to different industries, ensuring optimal performance for specific production needs.

Global Compliance – Our machines meet ISO 9001 and CE certification standards, guaranteeing quality and reliability.

Conclusion

Automatic thread rolling machines are revolutionizing the metalworking industry by providing high efficiency, superior precision, and cost-effective production solutions. From automotive to aerospace, construction, and heavy machinery, these machines have become an indispensable tool for manufacturers looking to improve productivity while maintaining exceptional quality standards.

If you are seeking to enhance your production capabilities with state-of-the-art thread rolling machines, contact us today for customized solutions designed to meet your specific industry requirements.

automatic thread rolling machine

PREVIOUS:

Contact Us

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.