Categories

Contact Us

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

HCG Automatic threading machine steel threading machine price

- Commodity name: HCG Automatic threading machine steel threading machine price

- Description

-

Designed with cutting-edge technology and user-friendly operation, Yushi threading machine steel delivers seamless performance for rebar thread rolling and pipe threading applications. This innovative machine combines rib stripping and straight thread rolling in one streamlined process, ensuring high automation and consistent quality for construction and industrial projects.

HCG Automatic threading machine steel threading machine price

Main features of HCG Automatic threading machine steel threading machine price :

1. Roll thread not cut thread, so could protect the highest tensile strength of parent metal. It meets requirements in JGJ107, ACI318, BS8110, DIN1045 and UBC1997 etc.

2. Easy to operate. Automatic opening-closing mechanism for rib peeling device, need only 30 seconds to finish a threaded end.

3. Peel ribs and roll threads by the same machine, so could save labor and improve productivity.

4. Widely used. Be able to process rebar diameter 16-40mm

5. Environment-friendly, safe, no environment and weather restrictions.

6. Economic, low investment for the equipmentHGS-40 HCG Automatic threading machine steel threading machine price Technical parameters:

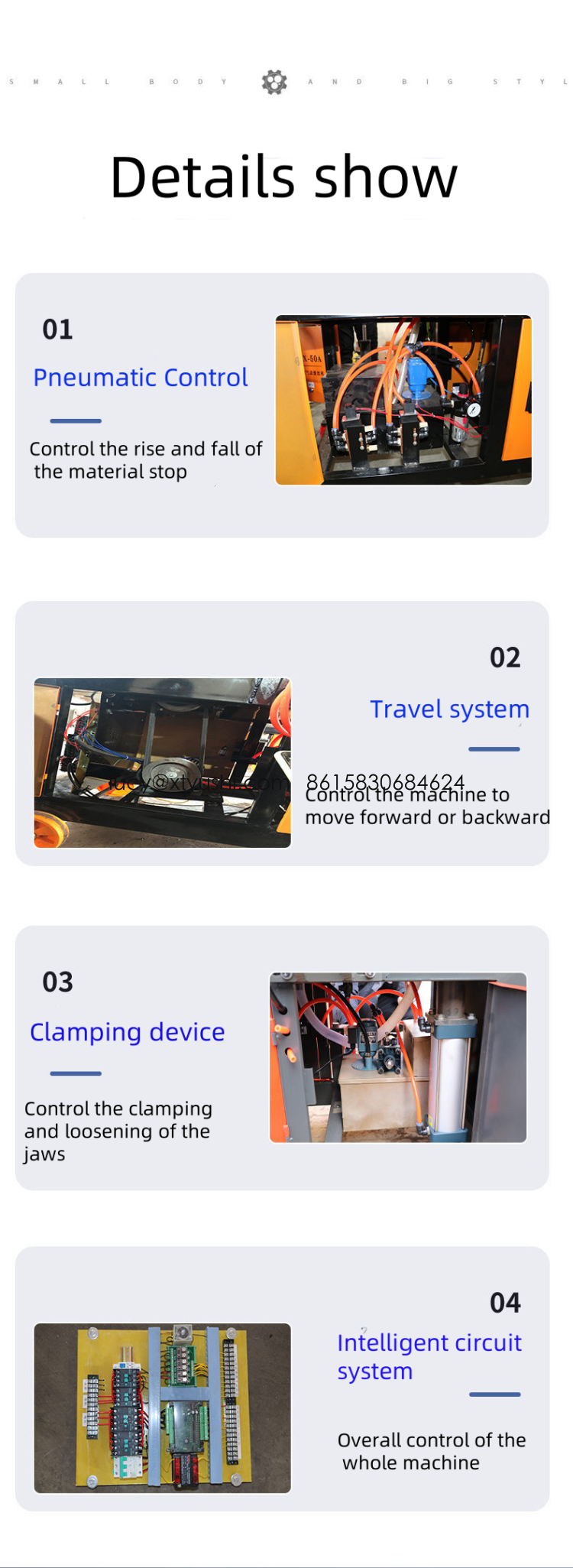

Production Name steel threading machine Machine weight 700kg Spindle speed 762/min processing range 16-40mm thread roller Divided rounds Standard frequency 60Hz production dimension 1900*800*1000mm Motor power 7.5kw Voltage 220V Oil pump motor 2.2KW thread length 200MM Head configuration Lengthen head HCG Automatic threading machine steel threading machine price detailed picture:

Why Choose Yushi as Your Supplier of Threading Machine for Steel?

-

Adjustable Precision:

The machine's adjustable cutters allow for microfine tuning of thread size, length, and pitch. With threading machine steel precision, operators can achieve consistent, high-quality threads that require minimal finishing work. -

Durability & Efficiency:

Featuring high-power motors (750W–1100W), nitrided gearboxes, and heat-treated dies, our machine stands out for its long-lasting performance. The cold-forming process not only enhances tensile strength but also minimizes material waste. -

User-Centric Design:

Lightweight models (around 75 kg) ensure mobility, while heavy-duty versions provide stability for prolonged projects. Automated systems reduce manual intervention, speeding up production and reducing labor intensity.

Operation and Performance

The process leverages a rotating cutter mechanism that impresses a thread pattern onto the ends of pipes or rebar, creating internal and external threads effortlessly. This method, intrinsic to threading machine steel technology, ensures that each thread is round, evenly spaced, and meets industry standards (BSPT/NPT). The efficient single-pass threading process operates quietly and without generating flammable sparks or abrasive dust.

Maintenance & Safety Guidelines

-

Pre-Operation Adjustments:

Replace rollers and washers according to the thread pitch and diameter needed. This precaution guarantees that the machine delivers the precise performance expected of a quality threading machine steel. -

Routine Maintenance:

Prior to commissioning, verify that the cooling water pump and electrical control systems function properly. Regular cleaning, especially around wiring and the iron core board, is essential to prevent short circuits and ensure long-term reliability. -

Component Care:

Replace worn contactors promptly to avoid operational downtime and maintain the machine's high efficiency.

workpiece processed by thread stripping rib rolling machine

Applications and Industry Use

Our threading machine steel is versatile, serving multiple industries:

-

Construction: Ideal for threading rebar and connecting steel reinforcements in structural joints and large-scale pipeline installations.

-

Manufacturing: Perfect for producing threaded rods, automotive fasteners, and industrial equipment parts.

-

Plumbing and Sanitation: Delivers leak-proof connections for steel pipe networks in water, gas, and heating systems.

Experience the superior performance and reliability of Yushi threading machine steel. Whether for construction, manufacturing, or specialized industrial projects, this machine is designed to meet rigorous standards and deliver exceptional results—proving time and again that threading machine steel is the trusted choice for professionals.

FAQ

1, Q: How about the after service?

A: We have a strong team, special for after service. We can arrange engineers to do service for you.

2, Q: Are you factory or trading company?

A: We are a factory in this field nearly 15 years

3, Q: Where is your factory located? How can I visit there?

A:Our factory is located in Xingtai City. Hebei province. You can fly to zhengding airport and or by high-speed train directly. I will pick you up .

4, Q:How does your factory do regarding HCG Automatic threading machine steel threading machine price quality control?

A:Quality is priority. We always attach great importance to quality controlling from the beginning.

5, Q: why choose YUSHI Machinery?

A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

-

Keywords:

HCG Automatic threading machine steel threading machine price

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products