Categories

Contact Us

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

Pneumatic Hydraulic Thread Stripping Rib Rolling Machine with Low Price

- Commodity name: Pneumatic Hydraulic Thread Stripping Rib Rolling Machine with Low Price

- Description

-

Yushi HGS-40: Precision Thread Rolling Machine For Bolt & Rebar Processing

The pneumatic hydraulic thread stripping rib rolling machine (Model HGS-40) from Yushi Machinery transforms construction workflows by integrating rib peeling and thread rolling into one powerhouse unit. This innovation eliminates multi-stage processing, slashing rebar threading time to 30 seconds while preserving tensile strength through cold-forming technology. Ideal for rebar diameters 16-40mm, it exceeds global standards (JGJ107, ACI318, DIN1045) and operates eco-efficiently at 220V/7.5kW.

Main features of thread stripping rib rolling machine:

1. Roll thread not cut thread, so could protect the highest tensile strength of parent metal. It meets requirements in JGJ107, ACI318, BS8110, DIN1045 and UBC1997 etc.

2. Easy to operate. Automatic opening-closing mechanism for rib peeling device, need only 30 seconds to finish a threaded end.

3. Peel ribs and roll threads by the same machine, so could save labor and improve productivity.

4. Widely used. Be able to process rebar diameter 16-40mm

5. Environment-friendly, safe, no environment and weather restrictions.

6. Economic, low investment for the equipmentHGS-40 thread stripping rib rolling machine Technical parameters:

Production Name thread stripping rib rolling machine Machine weight 700kg Spindle speed 762/min processing range 16-40mm thread roller Divided rounds Standard frequency 60Hz production dimension 1900*800*1000mm Motor power 7.5kw Voltage 220V Oil pump motor 2.2KW thread length 200MM Head configuration Lengthen head thread stripping rib rolling machine detailed picture:

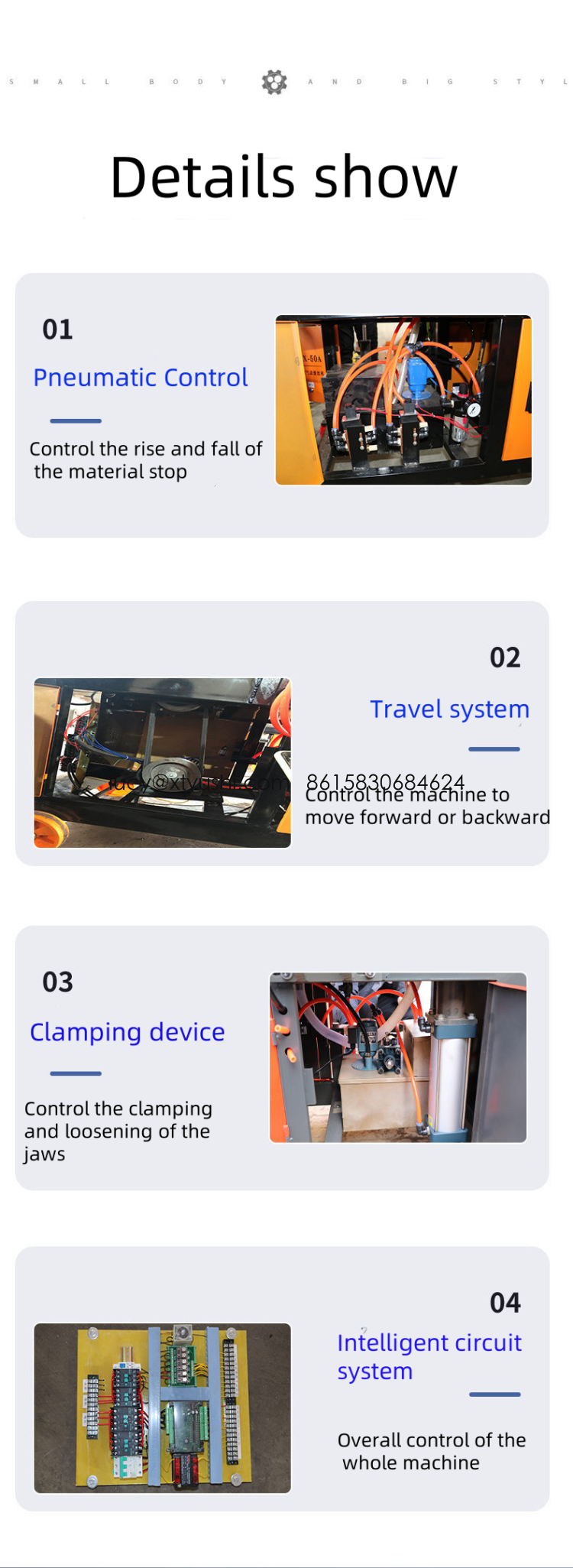

Key Advantages of Our Pneumatic Hydraulic System

Unmatched Automation & Precision

-

Dual-Process Efficiency: Rib stripping and thread rolling in one cycle.

-

Self-Actuating Mechanism: Auto-adjusting clamps for rapid loading/ejection.

-

Zero Material Waste: Cold-rolled threads maintain structural integrity.

Global Compliance & Cost Savings

-

International Certification: Complies with ACI318, BS8110, UBC1997.

-

Low Operational Costs: Minimal maintenance, no coolant dependency.

-

Eco-Safe Operation: Zero emissions, 24/7 functionality in all climates.

Step-by-Step Operational Guide

Step 1: Setup & Safety Protocols

Secure the pneumatic hydraulic thread stripping rib rolling machine on level ground. Wear OSHA-grade gloves/goggles. Verify 220V power and hydraulic oil levels.

Step 2: Material Preparation

Insert rebar (16-40mm) into the extended head. Optimize clamp pressure via the hydraulic panel.

Steps 3-4: Peeling & Threading

Activate automated rib peeling (15-second cycle). Switch to thread rolling mode (762 RPM spindle) – monitor precision via digital gauge (max 200mm length).

Step 5: Completion

Eject finished rebar automatically. Power down and clear residual debris.

Pro Maintenance Tips

-

Apply coolant for high-volume tasks.

-

Monthly calibration of the 2.2kW hydraulic pump.

-

Clean/lubricate peeling heads to prevent jams.

workpiece processed by thread stripping rib rolling machine

Why Yushi Machinery Leads the Industry

-

15+ Years Expertise: Factory-direct engineering and ISO-certified quality control for every pneumatic hydraulic thread stripping rib rolling machine.

-

Global Service Network: 24/7 technical support across 60+ countries.

-

Proven Reliability: Trusted by Tier-1 contractors for high-volume projects demanding precision.

As a premier Hydraulic Thread Rolling Machine Supplier, Yushi guarantees lifetime technical guidance and rapid spare-part dispatch. For structural applications requiring unyielding durability, the HGS-40 pneumatic hydraulic thread stripping rib rolling machine delivers unmatched operational excellence.

FAQ

1, Q: How about the after service?

A: We have a strong team, special for after service. We can arrange engineers to do service for you.

2, Q: Are you factory or trading company?

A: We are a factory in this field nearly 15 years

3, Q: Where is your factory located? How can I visit there?

A:Our factory is located in Xingtai City. Hebei province. You can fly to zhengding airport and or by high-speed train directly. I will pick you up .

4, Q:How does your factory do regarding thread stripping rib rolling machine quality control?

A:Quality is priority. We always attach great importance to quality controlling from the beginning.

5, Q: why choose YUSHI Machinery?

A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

-

Keywords:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products