Categories

Contact Us

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

High Speed Pneumatic Rebar Coupler Threading Machine

- Commodity name: High Speed Pneumatic Rebar Coupler Threading Machine

- Description

-

A Steel Rod Threading Machine works through a mechanical process combining rotation and pressing. Powered by a motor, the machine drives a threading tool or roller at high speed while firmly holding the steel rod in place. This process forms continuous threads on the steel rod's surface, which can then be connected using threaded steel sleeves for reliable and robust connections.

Key Components of Yushi Steel Rod Threading Machine

To ensure optimal performance, durability, and efficiency in demanding rebar threading machine operations, Yushi Steel Rod Threading Machines are engineered with premium components. Each part is meticulously selected and designed to work in harmony, delivering significant advantages over standard equipment:

-

Motor: Powering High-Speed, Reliable Processing

-

Advantage: Utilizes high-torque, energy-efficient motors specifically chosen for rebar threading machine applications. Provides robust and consistent power delivery for smooth operation under heavy loads and continuous use.

-

Boosts Performance & Efficiency: Enables faster threading speeds, reduces energy consumption per rod, and enhances machine stability for consistent thread quality. Minimizes downtime and maximizes threading productivity.

-

-

Reducer: Precision Speed & Torque Control for Flawless Threads

-

Advantage: Features a high-precision gear reducer system offering exceptional speed regulation and torque amplification. Superior heat dissipation and robust construction minimize vibration and ensure long-term reliability.

-

Boosts Performance & Efficiency: Critical for achieving high-precision threads with perfect pitch and depth. Reduces scrap rates, ensures compatibility with rebar coupler/sleeve connections, and contributes to smooth, vibration-free thread rolling operation, extending component life.

-

-

Rollers and Guide Plates: Unmatched Stability & Thread Accuracy

-

Advantage: Employs hardened, wear-resistant alloy rollers and precision-machined guide plates. Meticulously calibrated to provide exceptional rod clamping force and lateral support throughout the threading process.

-

Boosts Performance & Efficiency: Superior rigidity and alignment prevent rod deflection during high-speed thread rolling or rib peeling. Essential for achieving thread concentricity and consistent thread dimensions (pitch, major/minor diameter) crucial for reliable rebar splicing. Reduces vibration, protecting the spindle and enhancing machine durability and threading precision.

-

-

Processing Tools (Rollers/Cutters): Engineered for Durability & Versatility

-

Advantage: Core thread rollers and rib peeling cutters are crafted from premium tool steel using advanced heat treatment. Designed for extended service life handling a wide range of rebar diameters.

-

Boosts Performance & Efficiency: Long-lasting tools drastically reduce replacement frequency and cost, minimizing production interruptions. Ensures clean thread formation and efficient rib peeling, contributing to faster cycle times and higher threading machine output. Crucial for achieving the 30-second threading time per end and maximizing rebar preparation efficiency.

-

-

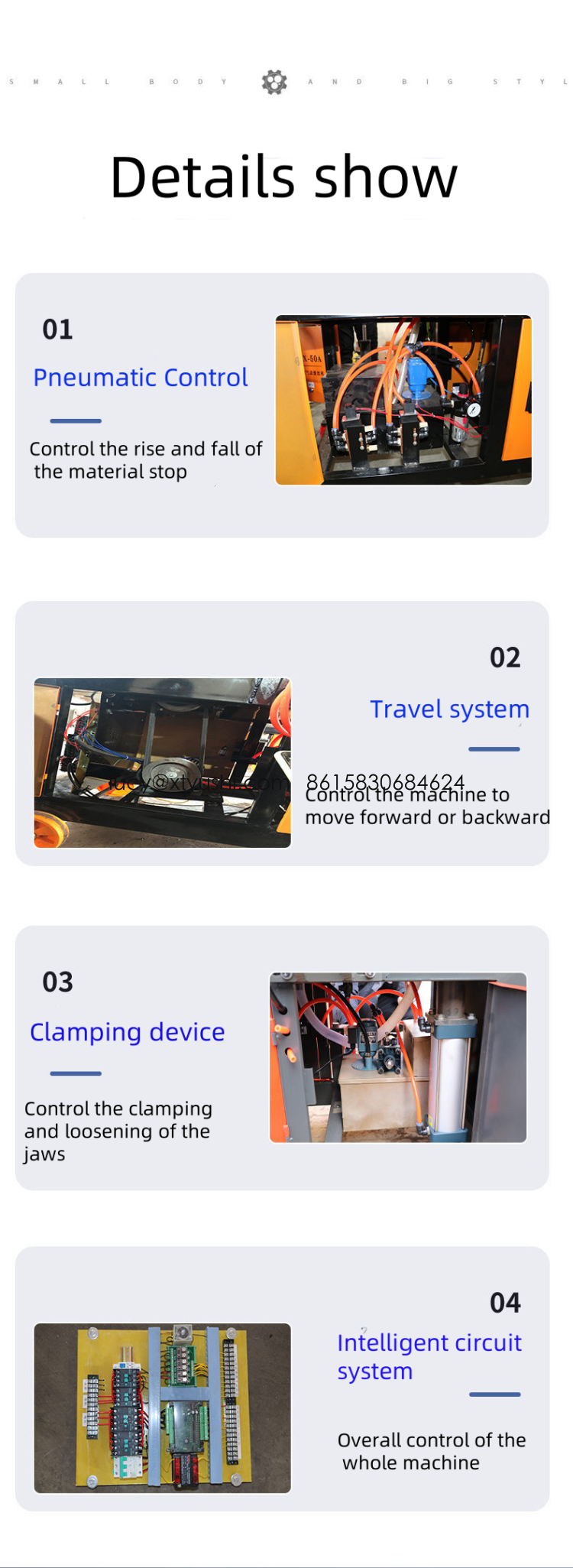

Control System: Intuitive Operation & Optimized Process Control

-

Advantage: Features a user-friendly, robust control panel (often PLC-based) for easy setting and monitoring of key threading parameters (speed, feed, thread length). Includes safety interlocks and clear status indicators.

-

Boosts Performance & Efficiency: Simple controls minimize setup time and operator errors. Precise parameter control ensures repeatable, high-quality results. Monitoring capability aids preventive maintenance, reducing unexpected breakdowns and optimizing overall rebar threading productivity.

-

A robust machine ensures smooth operation, long-term durability, and high performance in various threading applications.

HGS-40 Pneumatic rebar coupler threading machine price Technical parameters:

Production Name thread stripping rib rolling machine Machine weight 700kg Spindle speed 762/min processing range 16-40mm thread roller Divided rounds Standard frequency 60Hz production dimension 1900*800*1000mm Motor power 7.5kw Voltage 220V Oil pump motor 2.2KW thread length 200MM Head configuration Lengthen head Pneumatic rebar coupler threading machine price detailed picture:

Safety and Maintenance of Steel Rod Threading Machines

Safe Operation

Always ensure the working area is safe, equipment is functional, and power is stable. Adhere to safety guidelines and wear protective gear.Regular Maintenance

-

Clean debris from components.

-

Inspect fasteners and replace worn parts like rollers and cutting tools.

-

Proper maintenance extends the machine's service life and ensures consistent performance.

Workpiece Processed by Pneumatic Steel Rod Threading Machine

Choosing the Right Steel Rod Threading Machine Model

To select the best Steel Rod Threading Machine, consider these factors:

-

Type and Diameter of Steel Rods: Match the machine's capacity with your project requirements.

-

Processing Speed and Efficiency: Opt for a model that meets your production needs.

-

Level of Automation: Fully automated machines are ideal for large-scale projects.

-

Budget and Cost Efficiency: Invest in a durable and high-performing machine that minimizes maintenance costs.

Yushi's Steel Rod Threading Machines are designed for precision, durability, and user convenience. They provide high processing speeds, customizable thread lengths, and low maintenance requirements, making them a cost-effective solution for any project.

FAQ

1, Q: How about the after service?

A: We have a strong team, special for after service. We can arrange engineers to do service for you.

2, Q: Are you factory or trading company?

A: We are a factory in this field nearly 15 years

3, Q: Where is your factory located? How can I visit there?

A:Our factory is located in Xingtai City. Hebei province. You can fly to zhengding airport and or by high-speed train directly. I will pick you up .

4, Q:How does your factory do regarding Pneumatic rebar coupler threading machine price quality control?

A:Quality is priority. We always attach great importance to quality controlling from the beginning.

5, Q: why choose YUSHI Machinery?

A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.

-

Keywords:

Pneumatic rebar coupler threading machine price

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products