Categories

Contact Us

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

Z28-30 Automatic thread rolling machine for pipe and tube

- Commodity name: Z28-30 Automatic thread rolling machine for pipe and tube

- Description

-

Z28-40 Automatic thread rolling machine for pipe and tube

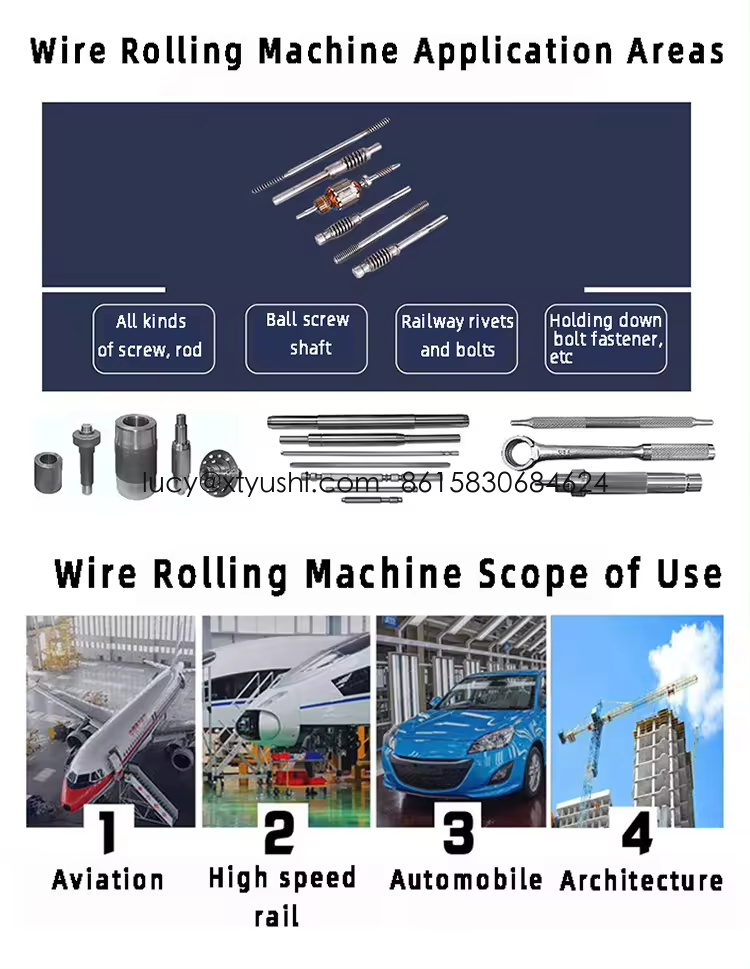

This Automatic thread rolling machine for pipe and tube is mainly used for cold rolling forming. Cold rolling process is an advanced chip free machining process that uses rolling tools for extrusion forming. The rolling of metal fibers is continuous, and the radial stress generated during rolling can effectively improve the surface smoothness, hardness, and strength of the workpiece. Compared to cutting processing, it improves work efficiency by several times, or even dozens of times, and can save materials, making it easier to achieve automated processing.

This Automatic thread rolling machine for pipe and tube is capable of rolling, straightening, polishing, reducing, and various forming and rolling of ordinary threads, diagonal lines, helical teeth, trapezoidal threads, and modular threads on cold workpieces within its rolling range. The machine tool has a safe and reliable electro-hydraulic execution and control mechanism. The rolling work cycle can be selected between manual and automatic (users can provide their own rollers as needed).

As a rolling tool, the thread rolling mould has strong specificity, and is applicable to various carbon steels, alloy steels and non-ferrous metals whose Hardness of rolling workpiece is not higher than HRC37, preferably lower than HRC25, elongation should be greater than 10%, and tensile strength should be less than 100Kgf/mm (square). With the increase of material hardness, the service life of rolling tools will decline sharply

ZP28-40 Automatic thread rolling machine for pipe and tube Technical paremeter

item parameter Thread rolling diameter renage max diameter ∅50mm max pitch 6mm spindle angle ±5° max rolling pressure 120kn spindle RPM Infinitely variable speed Thread rolling roller range outer diameter ∅65-140mm inner diameter ∅35/45mm maximum width 100mm rolling time 0.1-99.9s pause time 0.1-99.9s spindle drive power 4.0kw hydraulic transmisson power 1.5kw diamension 1400*1400*1500mm machine weight 1350kg

Automatic thread rolling machine for pipe and tube video

FAQ

1、How long is the warranty good for?

The whole Automatic thread rolling machine for pipe and tube is guaranteed for 1 year and the key parts are guaranteed for 2 years from the date of spontaneous shipment.

2、What payment methods do we accept?

We support bank cards, credit cards, T/T, etc.

3、What is our delivery time?

Normal delivery within 3 working days, special models can contact customer service consultation.

4、After-Sales Service

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

Keywords:

Pipe thread rolling machine-30

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products