Categories

Contact Us

E-mail :

Mobile/whatsapp/wechat::

Address:Xingjiawan Town Industrial Zone, Renze District, Xingtai City, Hebei Province.

Z28-30 Automatic wholesale pipe thread rolling machine

- Commodity name: Z28-30 Automatic wholesale pipe thread rolling machine

- Description

-

Roll Thread Rolling Machine – Precision Pipe Thread Rolling Machine for Superior Threading

Yushi Pipe Thread Rolling Machine is a cutting-edge solution designed to produce precise and durable threads on steel pipes, bars, and rods. This innovative equipment, known as a Pipe Thread Rolling Machine, integrates advanced cold-forming technology to deliver high-quality threads that enhance structural integrity. From the very first cycle, our Pipe Thread Rolling Machine ensures exceptional performance and reliability in high-volume industrial applications.

The Pipe Thread Rolling Machine is engineered to create threads by displacing material using high-pressure rotary or flat dies. Unlike traditional thread-cutting methods, our machine forms threads without removing metal, thus preserving the pipe's strength. This process, which is part of our advanced cold-forming technique, enhances mechanical properties through work hardening, making the threads up to 30% stronger than those produced by conventional methods. Additionally, our product line includes specialized models such as the 3 Roll Thread Rolling Machine and the Scaffolding Pipe Thread Rolling Machine to cater to a variety of threading needs across different industries.

ZP28-30 Automatic wholesale pipe thread rolling machine

Thread rolling machine: It is a multi-functional cold extrusion forming machine tool. The thread rolling machine can perform thread, straight and twill rolling on the workpiece in a cold state within the rolling force range; straight teeth, helical teeth and helical splines Gear rolling; straightening, reducing diameter, rolling and various forming rolling. Thread rolling machine: light, flexible, efficient, thread rolling plate processing, etc.

1. wholesale pipe thread rolling machine: It can process large-length and high-precision workpieces, with a market share of 70%. It is a multi-functional cold extrusion forming machine tool. The thread rolling machine can thread and straighten the workpiece in a cold state within its rolling force range. Grain, twill rolling and other processing; rolling of straight teeth, helical teeth and helical spline gears; straightening, diameter reduction, rolling and various forming rolling.

2. Screw making machine: It cannot process large-length and high-precision workpieces, and its market share is 30%. Light, flexible, efficient, wire rubbing board processing, etc.

3. To process m36*4 threads, select equipment according to the length and precision requirements of the workpiece.

What is the difference between a thread rolling machine and a thread rolling machine?

Thread rolling machine, no damage to the workpiece, cold extrusion.

The thread rolling machine needs to cut the workpiece.

ZP28-40 wholesale pipe thread rolling machine Technical paremeter

item parameter Thread rolling diameter renage max diameter ∅50mm max pitch 6mm spindle angle ±5° max rolling pressure 120kn spindle RPM Infinitely variable speed Thread rolling roller range outer diameter ∅65-140mm inner diameter ∅35/45mm maximum width 100mm rolling time 0.1-99.9s pause time 0.1-99.9s spindle drive power 4.0kw hydraulic transmisson power 1.5kw diamension 1400*1400*1500mm machine weight 1350kg

Automatic thread rolling machine for pipe and tube video link on youtube

Key Features

-

Cold-Forming Technology:

The Pipe Thread Rolling Machine uses cold rolling to plastically deform the surface of pipes, ensuring that no scrap is generated and that the thread quality is enhanced through work hardening. -

High-Speed Production:

With rotary die systems capable of producing up to 80 threads per second, our Pipe Thread Rolling Machine significantly boosts production efficiency for large-scale manufacturing. -

Adjustable Dies and Precision Controls:

Featuring CNC-controlled adjustments, the machine accommodates multiple thread standards (e.g., NPT, BSP) and can be calibrated for varying pipe diameters, ensuring consistent thread pitch and depth. -

Integrated Lubrication System:

Built-in lubrication reduces friction, minimizes defects, and improves the surface finish of threads, ensuring that the Pipe Thread Rolling Machine operates smoothly and with minimal downtime. -

Robust and Durable Design:

Constructed with hardened steel dies and a resilient feeding mechanism, our Pipe Thread Rolling Machine is built to handle high-stress, continuous production while maintaining excellent performance.

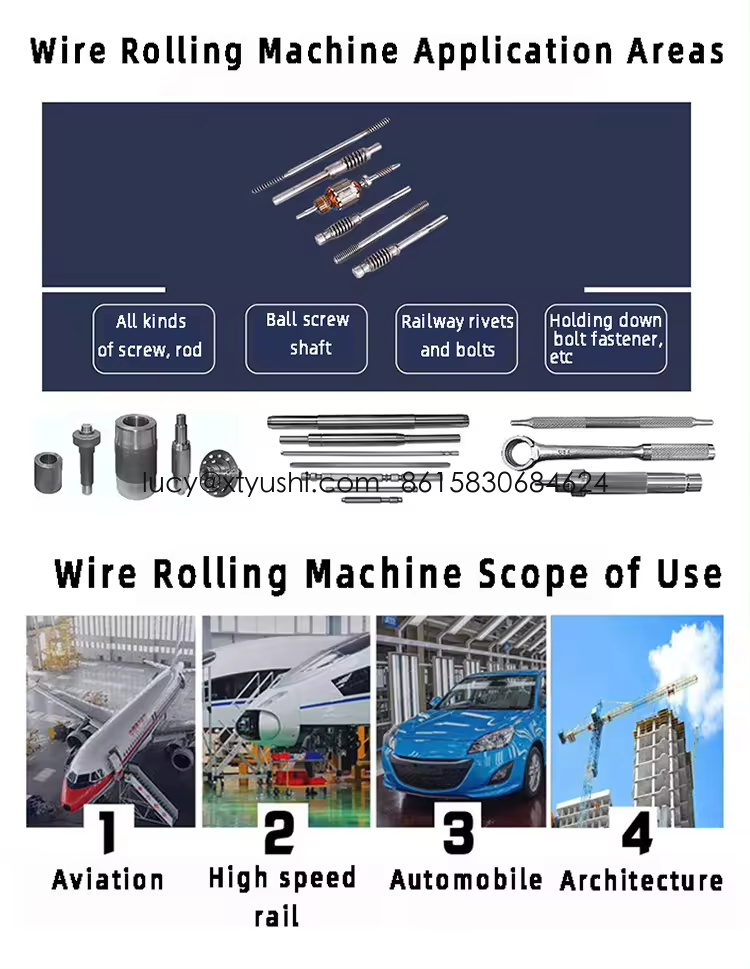

Applications

-

Construction:

Widely used in threading steel reinforcement bars (rebar) for secure structural connections in buildings, bridges, and infrastructure projects. -

Industrial Manufacturing:

Ideal for producing threaded rods, automotive fasteners, and machinery components where high precision and durability are required. -

Plumbing and Pipeline Installations:

Used to create leak-proof threaded connections in steel pipes for water, gas, and heating systems, ensuring reliable performance. -

Infrastructure Projects:

Essential for large-scale projects that require robust and consistent threads to ensure safety and longevity in critical installations. -

Custom Fabrication:

The machine is also suitable for producing custom threaded components for specialized industrial applications, offering flexibility and high efficiency.

Yushi Pipe Thread Rolling Machine stands out as an indispensable tool in modern manufacturing, providing precision, efficiency, and enhanced mechanical strength through advanced cold-forming technology. From the initial setup to the final production cycle, our Pipe Thread Rolling Machine delivers unmatched quality and consistency, making it the trusted choice for industries ranging from construction to industrial manufacturing—ensuring that our Pipe Thread Rolling Machine remains the top solution for superior threading.

Roll Thread Rolling Machine – Essential Guide for Safe and Efficient Operation of Pipe Thread Rolling Machine

Our Pipe Thread Rolling Machine is a critical component for high-quality thread formation in the construction industry. Designed with advanced technology, this Pipe Thread Rolling Machine ensures precision and durability from the very first cycle, making it indispensable for efficient rebar threading.

Worker Training and Certification

To ensure the safe operation of the Pipe Thread Rolling Machine, all operators must undergo mandatory technical training and pass a skill assessment before they are allowed to operate the equipment. Teams should consist of fixed, trained personnel to maintain consistency and uphold safety standards. This training ensures that every operator is fully equipped to handle the Pipe Thread Rolling Machine in both routine and emergency situations.

Equipment Debugging and Testing

Prior to formal production, it is crucial to perform thorough pre-production testing of the Pipe Thread Rolling Machine. Debug the equipment completely and confirm that all functions operate correctly. Production should only begin once the Pipe Thread Rolling Machine has been verified to work seamlessly.

Steel Bar Cutting and Preparation

-

End Face Preparation:

Ensure the end face of the steel bar is perpendicular to its axis and free from imperfections (e.g., horseshoe shapes or arches) before processing on the Pipe Thread Rolling Machine. -

Straightening Requirement:

If the end of the steel bar is not perfectly straight, it must be corrected prior to cutting to ensure accurate threading.

Steel Bar Head Roughening

-

Roughening Process:

Roughen the head of the steel bar before threading on the Pipe Thread Rolling Machine. Reset the roughening machine to zero before starting, ensuring the bar is correctly inserted and securely tightened. -

Quality Control:

Inspect the roughened heads for uniformity. Discard and re-roughen any heads that do not meet quality standards, and avoid re-roughening the same head more than once.

Quality and Safety Checks

-

Inspection:

Inspect the roughened section for any transverse cracks, and use appropriate threading methods along with water-soluble cutting fluid during operation. -

Cold Weather Precautions:

For temperatures below 0°C, implement anti-freezing measures and avoid adding cutting fluid during the threading process to maintain the integrity of the Pipe Thread Rolling Machine.

Pre-Shift and Post-Shift Procedures

-

Pre-Shift Equipment Check:

Before each shift, run the Pipe Thread Rolling Machine empty to check its operational condition. Verify the normal rotation of the machine head, the adequacy of the cutting fluid, the sensitivity of electrical switches, and the tightness of screws. -

Post-Shift Maintenance:

After each shift, clean iron filings from the pier head, fixtures, and molds. Replace cutting fluid as necessary and lubricate the guide rod and rotating parts to ensure ongoing optimal performance of the Pipe Thread Rolling Machine.

Maintenance and Safety Compliance

-

Timely Maintenance:

Address any equipment failures immediately. Perform maintenance on high-pressure oil pumps indoors in a dust-free environment to prevent contamination. -

Authorized Operation and PPE:

Only trained and certified personnel should operate the Pipe Thread Rolling Machine. Operators must wear safety helmets and secure their clothing appropriately (gloves are not allowed during operation) to minimize risk. -

Compliance and Education:

Adhere to all safety management regulations and conduct regular safety training sessions. This ensures that all personnel remain aware of potential hazards and maintain a safe working environment.

Additional Equipment Considerations

Our product range also includes specialized models like the Roll Thread Rolling Machine for general threading applications and the Scaffolding Pipe Thread Rolling Machine for large-scale, infrastructure-specific tasks. These models further expand the capabilities of our threading solutions, providing versatility and tailored performance for different industrial needs.

FAQ

1、How long is the warranty good for? The whole wholesale pipe thread rolling machine is guaranteed for 1 year and the key parts are guaranteed for 2 years from the date of spontaneous shipment.

2、What payment methods do we accept?

We support bank cards, credit cards, T/T, etc.

3、What is our delivery time?

Normal delivery within 3 working days, special models can contact customer service consultation

4、After-Sales Service

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas. -

Keywords:

wholesale pipe thread rolling machine

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products